The envelope type dust removal skeleton is formed by one-time welding of equipment, characterized by firm welding and a smooth and straight appearance. The envelope type dust removal skeleton is the rib of the filter bag, and the quality of the dust removal skeleton directly affects the working condition and service life of the filter bag.

The envelope type dust removal skeleton is the rib of the filter bag, which should be lightweight, easy to install and maintain. The quality of the envelope type dust removal skeleton directly affects the filtering state and service life of the filter bag.

The envelope type dust removal skeleton has different dust removal mechanisms and dust collectors used for dust with high fiber content compared to general dust. There are two working principles for dust collectors in the textile industry, namely filtration mechanism and centrifugal separation mechanism.

The envelope type dust removal framework is mainly used in electrostatic precipitators, which are devices that use electrostatic purification to collect dust from flue gas. It is an ideal equipment for purifying industrial waste gas.

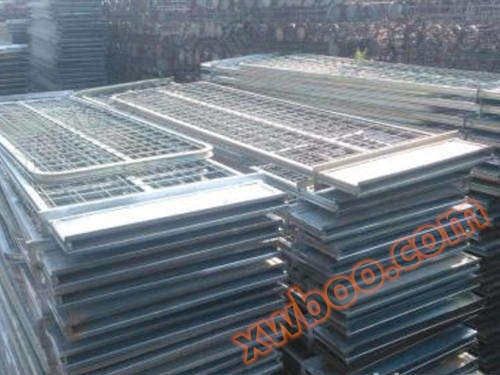

The envelope type dust removal skeleton is made using processing technology, which can provide sufficient service life and lifespan, as well as sufficient quality of use. The framework of the dust removal filter bag has good structural characteristics and performance. Due to the use of ceramic heating materials with automatic constant temperature characteristics and high-performance insulation and temperature resistant materials, coupled with excellent structural design, its normal service life can reach 5-10 years. Use iron wire or stainless steel wire with sufficient strength and rigidity, galvanized, sprayed, silicon plated and other treatment methods. The skeleton processed by silicon technology can replace stainless steel skeleton, which can reduce the maintenance cost of equipment.

The mechanism of filtration and dust removal is the comprehensive effect of short-range capture mechanisms such as screening effect, diffusion settling, direct interception, inertial collision, and electrostatic adsorption. When the dusty air passes through the filter media such as grids, fabrics, nonwovens, foamed plastics, etc., the dust layer formed by the dust inside or on the surface of the filter media, and the filter layer formed by the upper layer of the powder are trapped to separate it from the air flow. As the dust layer thickens, it is necessary to schedule the dust layer for continuous dust removal process. Textile fiber dust collectors are classified according to their structural forms, including cage filters, filter bag filters, and packed filter bed filters.

All welding points of the envelope type dust removal skeleton should be firmly welded, and there should be no loose welding, virtual welding, or missed welding.

The surface of the envelope type dust removal skeleton in contact with the filter bag should be smooth and clean, and no welding scars are allowed. Uneven and rough surfaces with burrs.

The envelope type dust removal skeleton should have sufficient number of turns and elasticity, and the spacing should be even after opening.

The surface of the envelope type dust removal skeleton has been treated and electroplated according to different needs. Spraying or painting, if used for high temperatures, should meet the requirements of the operating temperature.

The envelope type dust removal skeleton is made using processing technology, which can provide sufficient service life and lifespan, as well as sufficient quality of use.